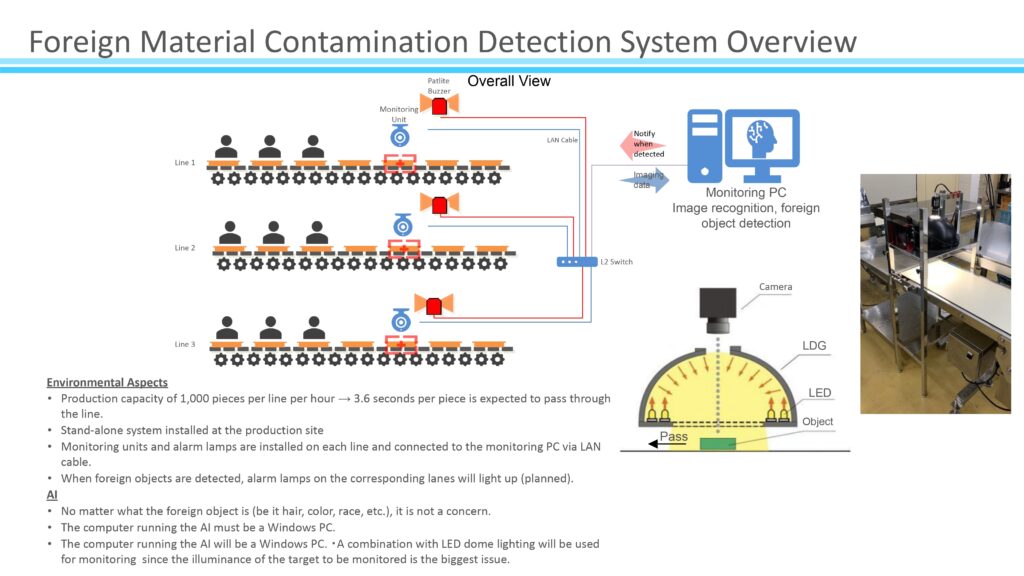

AI imaging detects hair and foreign objects.

AI-based visual inspection Trackbott

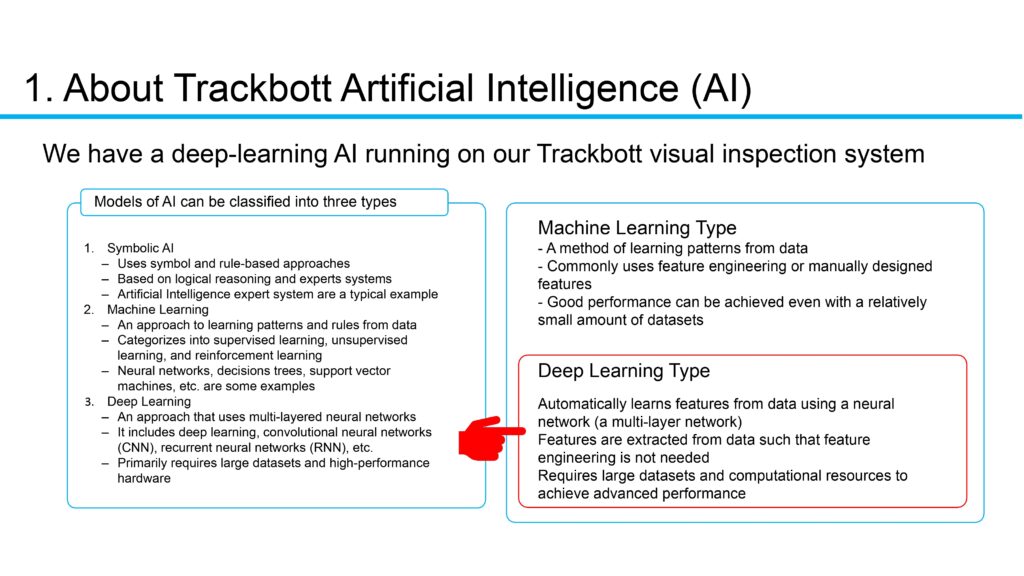

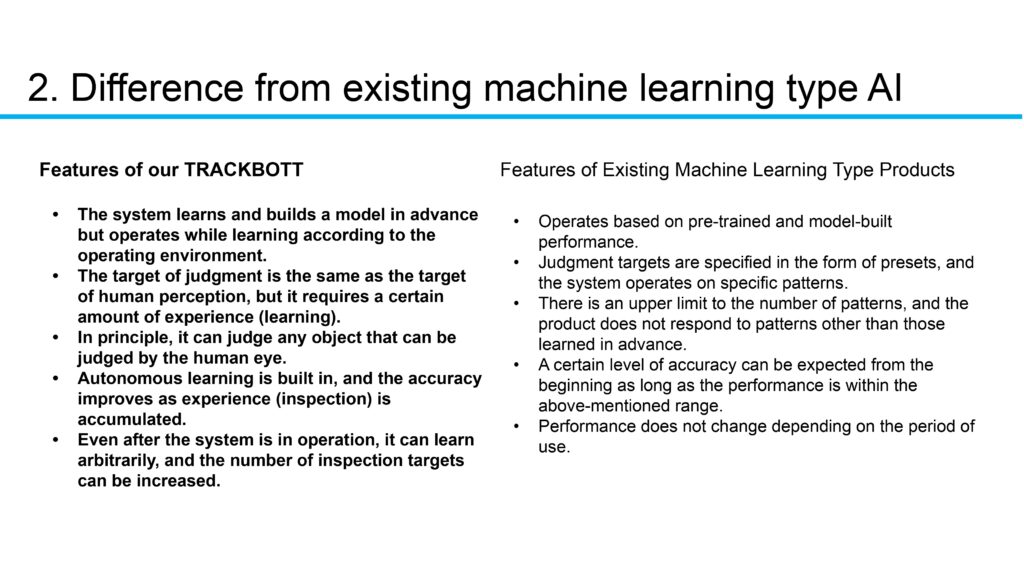

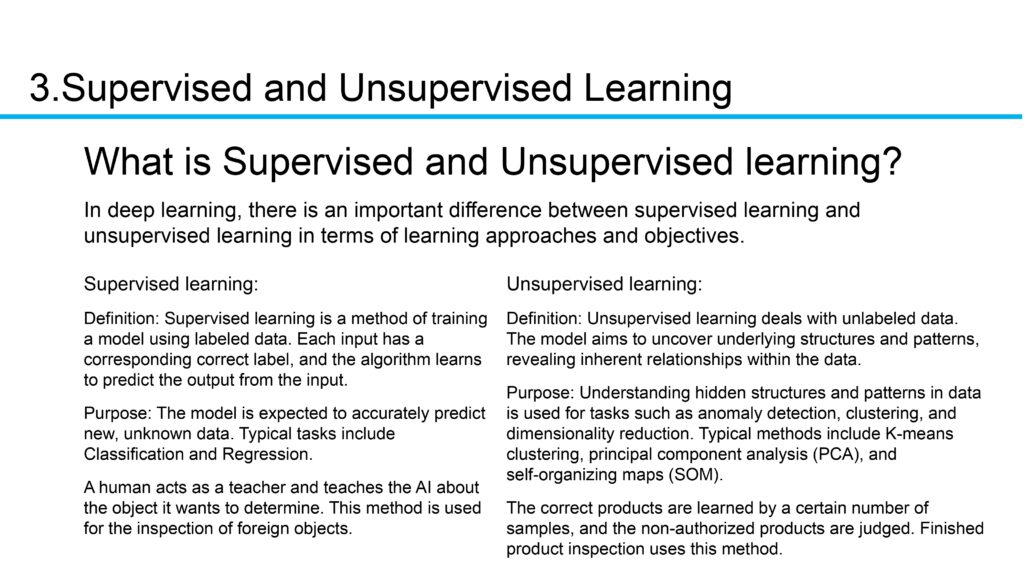

AI General Summary

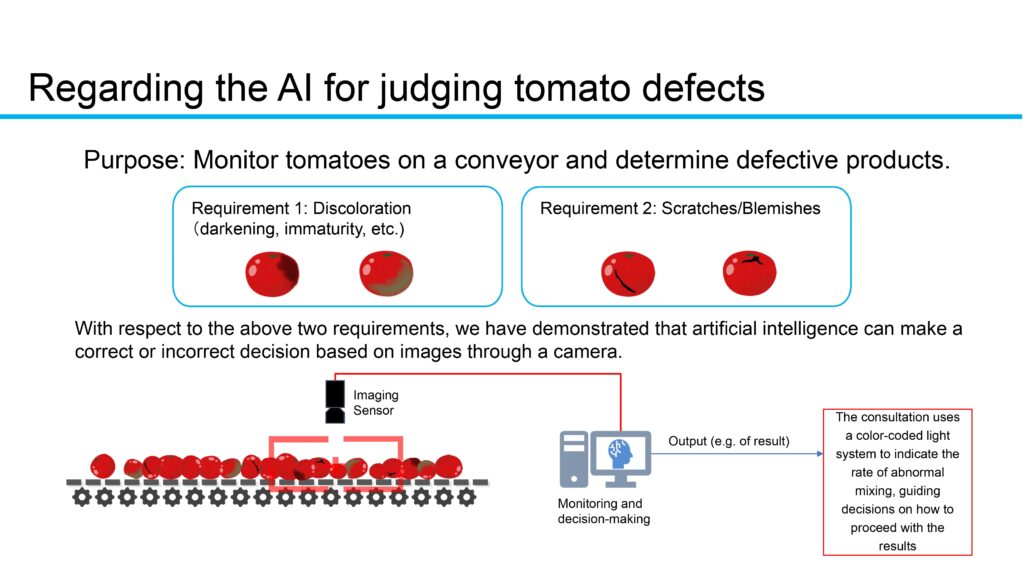

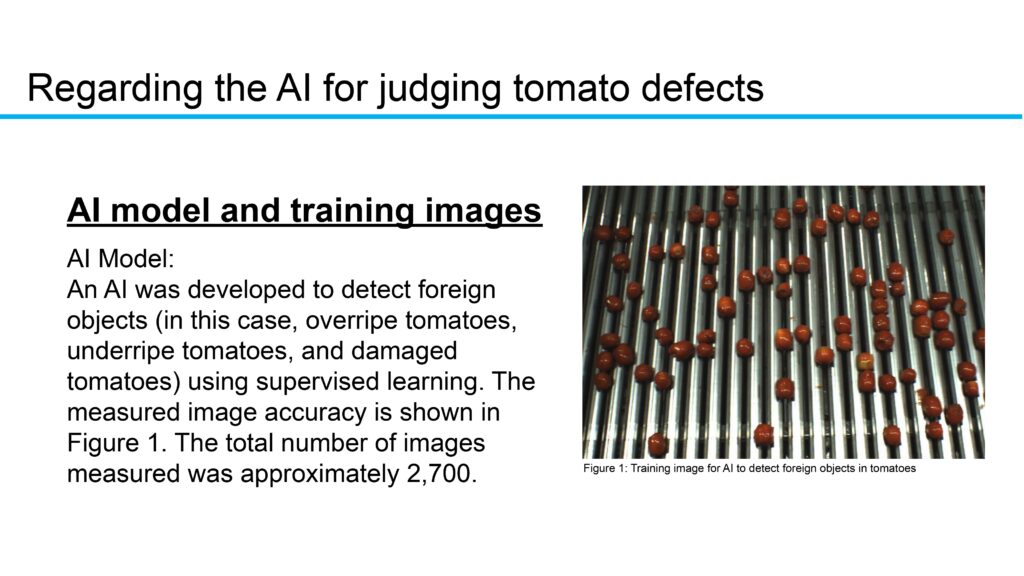

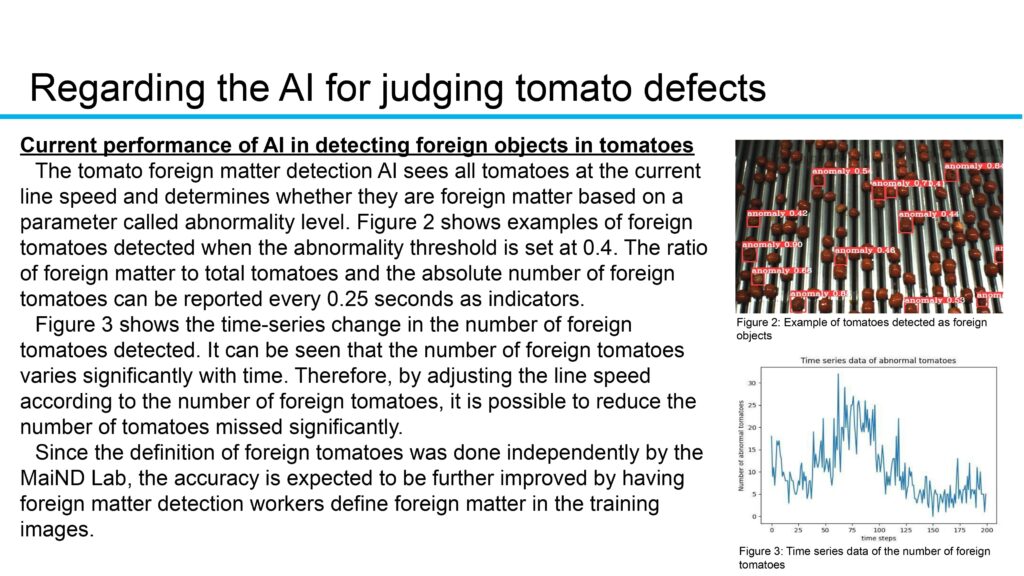

Tomato defect inspection AI

Label discrepancy inspection AI

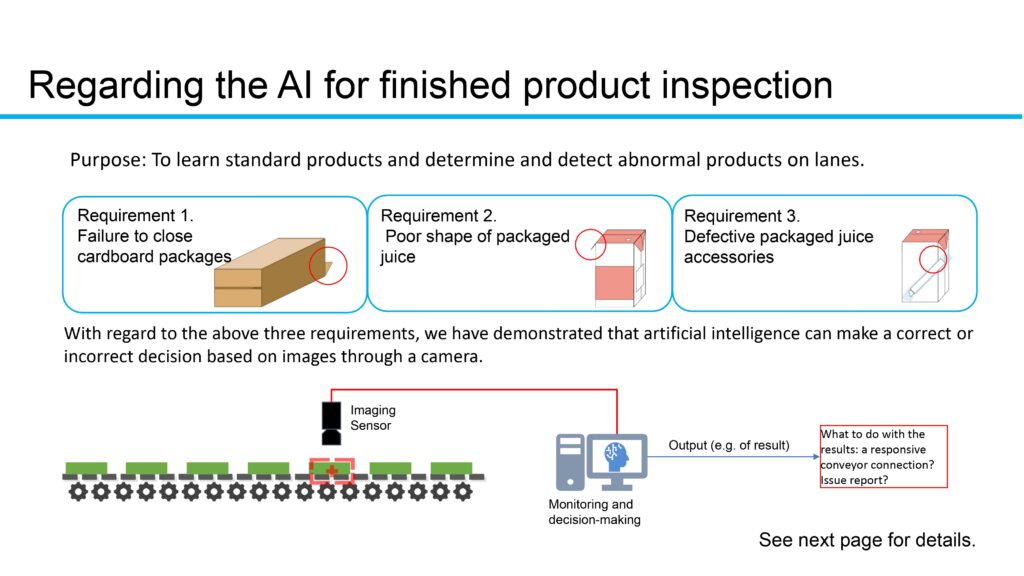

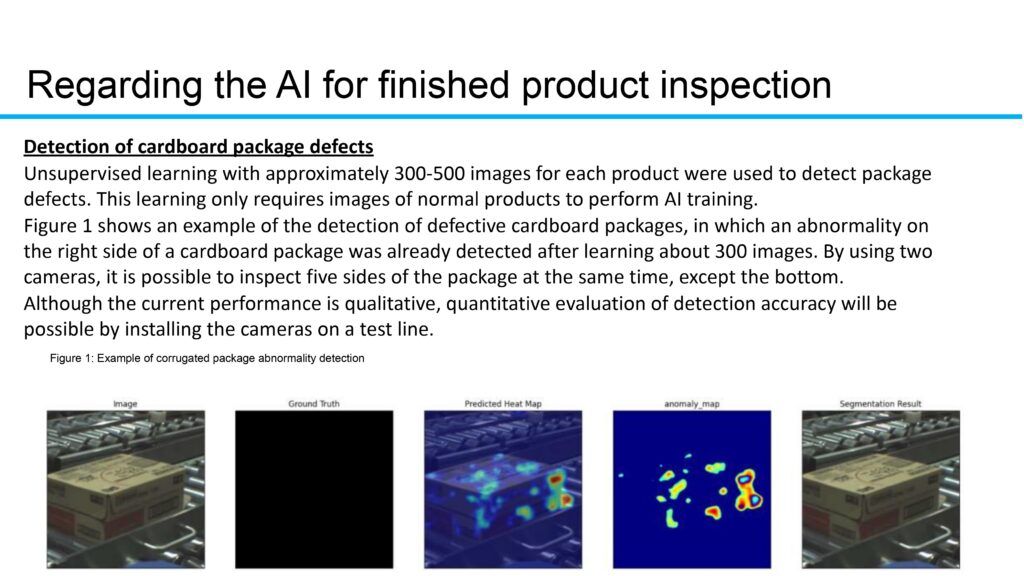

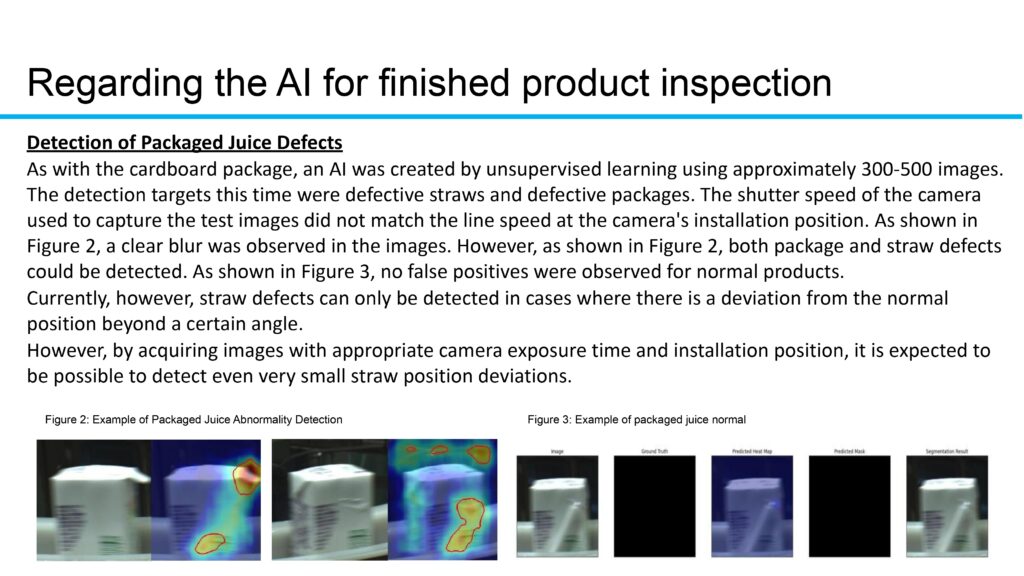

Finished product inspection AI

Contact us

1115 Broadway, 12th Fl, New York , NY 10010 USA

Univa America, Inc.

E-mail : oshiro@univaamerica.com

PHONE : 212-386-7603

Univa America, Inc.

E-mail : oshiro@univaamerica.com

PHONE : 212-386-7603